Butterfly valves for seawater traveled around the world

Other valves from ARMATURY Group traveled around the world.

This nuclear power plant is supposed to be the largest in India. Its construction began in 2002, but due to the difficulty of getting the material for the construction, the first reactor was put into operation in 2013, the second reactor a year later.

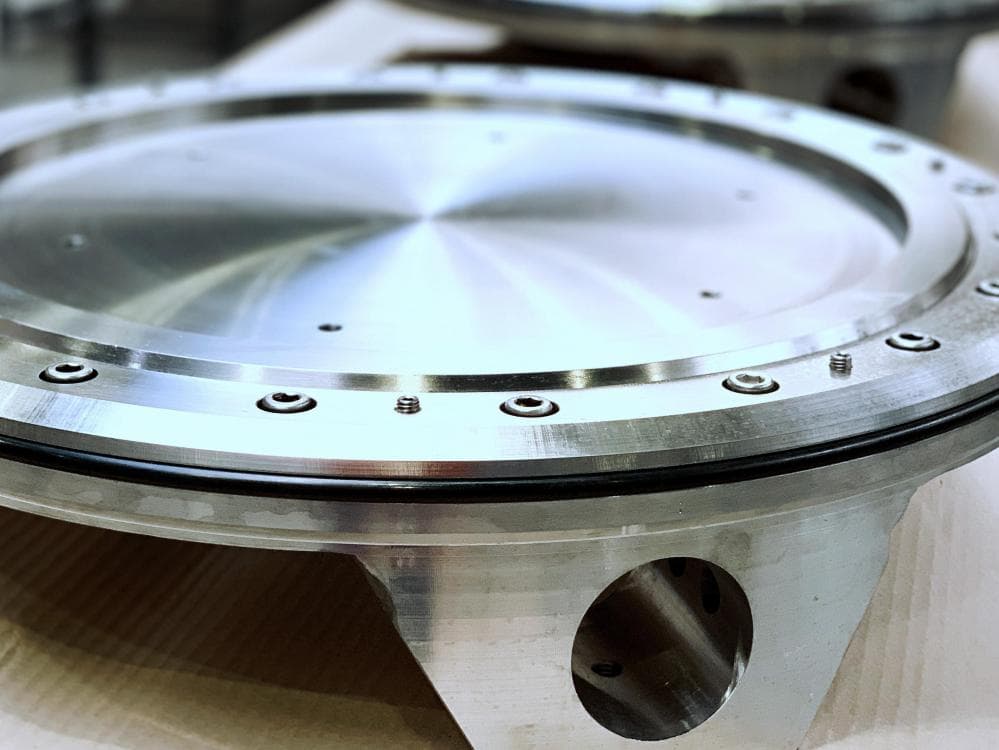

Last year, a contract for the supply of a total 58 pieces of valves was signed. These were butterfly valves AL32 for this Kudankulam Nuclear Power Plant. A large part, a total of 42 pieces of butterfly valves in diameters DN 400 to DN 800 with AUMA electric actuators, were dispatched at the end of 2021. The butterfly valves operate on the supply pipe from the sea to the cooling towers of the Kudankulam Nuclear Power Plant for the third and fourth units.

Specific requirements

The butterfly valves are unique in their design solution, with which the power plant has experience from the first and second units. Due to the very aggressive seawater of the Indian Ocean, most stainless-steel materials are unusable for this medium. That is why the designers of ARMATURY Group together with VSB – Technical University of Ostrava have designed a technical solution that meets the requirements for the protection of the basic material.

On the disc of the butterfly valve are placed retread (protective) plates, which are easily replaceable and with regular maintenance ensure a long-term service life of the valves, which is required for the Kudankulam Nuclear Power Plant for 30 years.

Due to the fact, that the customer insisted on the stainless-steel material of the butterfly valves, carbon material retread plates were designed on the discs to protect the base material from aggressive seawater and to protect against the corrosion. This year, ARMATURY Group will produce and deliver another 16 pieces of butterfly valves, safety class two.

For more information:

Sales Manager Eastern Europe | GAS