High-pressure gate valves, type S43 AG

At our online newsletter VALVES360, you could find much information about industrial valves, which company ARMATURY Group manufactures and supply to its customer. In this issue, we will expand your knowledge with a high-pressure gate valves S43.

High-pressure valves are special type of valves, which are used especially in power engineering. Its working medium is water and high-pressure steam. This type of valves has been produced in ARMATURY Group since 2007.

Gate valves S43 can be developed into these three main groups:

Type S43.5 for steam and water

(see picture 1)

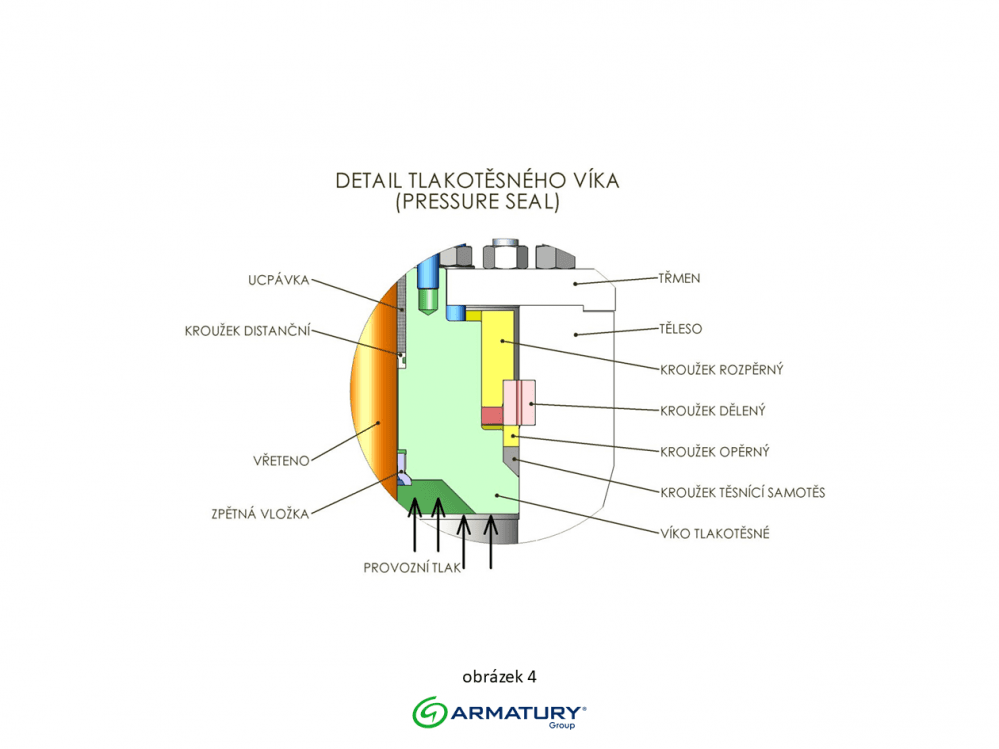

The range of this type of valve is from PN 160 to PN 400 and from DN 50 to DN 600. This is a basic series following the type S41, historically dating back to the 1970s. Gate valves AG are designed with pressure seal bonnet, which is a special design of bonnet for high pressure and temperatures (see picture 4). The sealing ring is from expanded graphite, manufactured in appropriate shape form. The body and the bonnet are always made from forging. Design with flexible wedge and rising stem. The gate valve is standardly operated by electric actuator or by manual hand wheel. Based on customer’s requirements it is possible to design the valve with operation by pneumatic actuator or hydraulic traction actuator, or it is possible to equip the valve with actuator located out of the valve on the control stand, for placing the valve above or under the floor.

This gate valves are designed for extreme working conditions. The temperature of the steam standardly reaches 555 °C and the pressure is at this temperature mostly 13,6 MPa. At the supercritical power plant block can, the temperatures reach up to 600 °C. In case of the supply water, it is temperatures around 225 °C and the pressure 22,5 MPa.

Forged gate valves S43.5 are necessary and integral part in various power plants and heating plants not only in the Czech Republic, but also throughout Europe.

Type S43.1 for gas, including hydrogen

(see picture 2)

The range is PN 63 and PN 100, DN 50 up to DN 350. This is a series, which was created based on the market requirements. These are gate valves, where the body and the bonnet are forged. The bonnet joint is in this case created with help of a flange joint. These gate valves made from forged materials can be used for example for gas including hydrogen. Alternatively, it is used in location, where there are higher demands on the quality of the body material, due to the working medium, which is steam.

Type S43.3 for natural gas

(see picture 3)

PN 16 up to PN 100, DN 50 to DN 400. It is a series of gate valves for natural gas transmission. Body of this gate valves are based on the concept of forged ensemble. The rest of the construction is completely different, construction is based according to the delivery conditions of customer. The conditions consider the standard EN 14141 "Valves for the transport of natural gas". The design is with no rising stem, instead of the classic seal, the stem is sealed with several levels of sealing, using “o” rings. In the most cases are those gate valves ARMATURY Group manufactured in welding design, for underground location, with control via stand of different lengths, according to the required burying depth. Currently, the company ARMATURY Group performs modifications of the design of the body to the body design from formed semifinished products, tube + arched bottom. This solution will bring efficient production of the body, and it will reduce laboriousness during machining. Gate valves S43.3 are necessary part of the gas pipeline.

Advantages that meet high demands

For all three types of gate valves, the sealing surfaces are welded with a Stellite 6. This type of weld shows resistance to high temperatures and is resistant to steam. And it is the only material that meets the requirements for the allowable contact pressure on the sealing surfaces of the wedge and seats.

Materials to produce bodies, lids and wedges are determined according to the customer's requirements (pipe material) and depending on the operating parameters. These are carbon steels, e.g., 1.0460, through alloy steels 1.7715 or 1.7335, up to steel type 1.4903, which is for the most demanding applications up to 650 °C. Forged semifinished products are used, which guarantee 100% material quality.

The control methods are listed above. Of course, it always depends on the requirements and agreement with the customer, what type of control is made for the gate valve.

Furthermore, the gate valves can be equipped with a bypass. The bypasses are used to equalize the start pressures or to gradually heat the pipes. A more detailed description of the possible equipment is always given in the relevant Installation and Operating Instructions for the individual types of valves.

For more information

Petr Postulka, designer