It all starts with technical consultation

Our company is a manufacturer of a wide range of valves in the field of energy, gas, metallurgy, and petrochemistry.

From the very beginning, we listen as much as possible to customer requirements and we are looking for suitable optimal solutions and if necessary, flexibly modify our products based on these requirements while maintaining cost-effectiveness.

An above-standard approach from the very beginning

As part of the orders, the company usually provides above standard consultation and advice, the aim of which is to eliminate mistakes in the application of supplied valves as much as possible. ARMATURY Group has a large team of experienced technicians and designers who are equipped with modern computing tools.

The team of experts has many years of experience in the field of valves as well as from cooperation with universities and specialized research and experimental organizations. Thanks to the service which ARMATURY Group provides to its customer, it thus gains direct contact with the operations where the valves are located and used. This gives technicians the best feedback.

“The resources and efforts that our company invests in consulting are returned to us in the form of a satisfied customer with perfect and long-term functionality of the valves. Such a customer is happy to return to us. We offer our customers two basic areas of consulting activities, both within the tender procedure and in the implementation phase of a specific order,” describes the technical director of ARMATURY Group Petr Heider.

We are looking for the optimal solution. Already in the phase of the offer, we try to choose the optimal solution in cooperation with the customer. These are mainly the following activities with the selection and completion of important parameters that are needed to select a suitable valve:

- Selection of a suitable type of valves for the given parameters

- shut-off valves – check valve, ball valve, gate valve (cats, welded, forged), shut-off globe valve

- control valves – control globe valve (characteristic type, with single plug), control gate valves, control check valve, special multistage globe valve for high-pressure drops

- check valve – check valve (balanced or with large counterweight, with damper, butterfly valve, with actuator)

- ball valve (floating or supported ball, bypass, what type of bypass)

- Choice of suitable diameter, pressure class, and material design of the valve

- Definition of the material sealing elements, surface treatment, type of possible welds or metal coating

- Determination of control torques and forces, suitable drive parameters, and its type

- For actuator manufactured in ARMATURY Group, determination of the size of weights, hydraulic cylinder, magnet, damper, etc.

- Elaboration of various characteristics describing the expected behavior of the valve on the given parameters; calculation of hydraulic resistance

- Proposal for the solution of special requirements (various ways of providing protection against an inadmissible increase in the pressure of a closed liquid by heating from the outside)

Why is calculation important

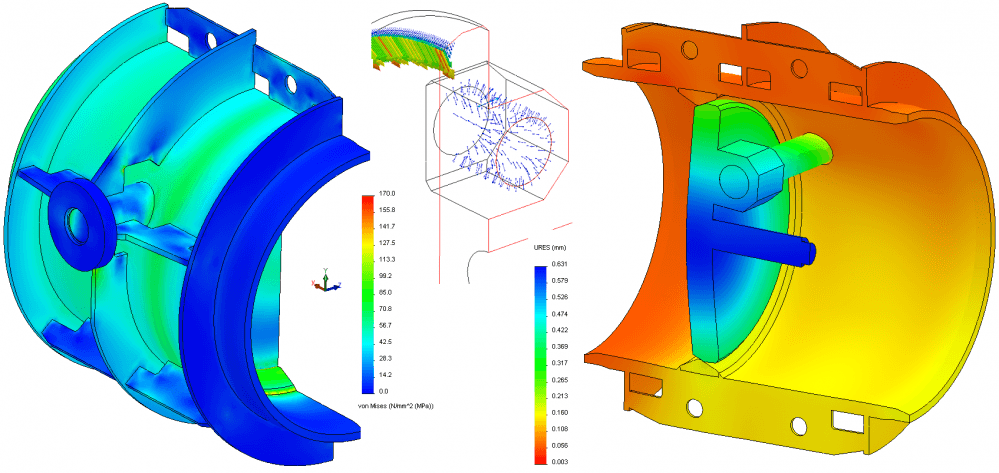

Technical support does not end with ordering the valve. It is time to assess whether the valve meets the customer's requirements in terms of strength and functionality. In addition to the standard strength calculations performed on each type of valve size, calculations can also be performed according to special requirements, requiring good cooperation with the customer. Here are some of the most frequently performed analyzes:

- assessment of the resistance of the valve to loading loads from the connected pipeline,

- temperature study - for example, calculation of the temperature at the sensor site, which can withstand only a certain temperature,

- calculation of fatigue under cyclic loading, the requirement for extended service life,

- solving the requirements for an unusually high coefficient of safety against yield strength,

- calculation of resistance to thermal shocks,

- assessment of seismic resistance of the valve,

- demanding media - seawater, hydrogen corrosion, abrasion, media with extreme temperatures,

- flow calculations (CFD) - shape optimization to minimize pressure losses at hydroelectric power plants, pressure loss calculations for atypically placed valves, calculations of hydrodynamic effects - moments and forces acting on the valve and adjacent pipelines, heat dissipation calculations.

"There are always a lot of questions and it is our task to find the most suitable solution for a specific situation. We are aware that we are experts in valves and our customer expects the best and most suitable solution from us at an affordable price. As one of our important customers once told us: Valves are not buns in a shop. We at ARMATURY Group are very well aware of this and we try to fulfill customer wishes to the maximum, "concludes Petr Heider.