Vexve's smart leakage detection system helps Fortum in the monitoring of district heating networks

The transfer line from Fortum Power and Heat Oy's new bioenergy plant in Kivenlahti is equipped with alarm wires installed in insulation, which are connected to Vexve's iSENSE Pulse leakage detection system.

The system enables real-time leakage detection and accurate locating of leakages through pulse measurement technology. With the help of iSENSE Pulse, Fortum detected leakages already during the network's warranty period, and they could be repaired well in advance before significant damage occurred.

iSENSE Pulse is part of Vexve's new iSENSE product family. The real-time measuring data received from the iSENSE products help to improve the efficiency of the network, create tools for preventing condition monitoring, and make leakage detection faster. The product family was launched in 2019 and already in the first year, savings have been achieved with it, as well as strengthening the delivery reliability of district heating.

The biggest threat for new district heating lines is external moisture

External moisture that gets inside the insulation pipe is the most significant risk factor for modern pre-insulated piping systems and at the same time, it is also the most difficult to detect. Already in a short time, moisture can cause corrosion of pipes and in the end, a leakage. The accumulation of external moisture can be detected only using alarm wires placed inside the insulation and an alarm system connected to them.

"It is generally thought that a leakage detection system is not needed for new networks because typically, leakages occur in old lines. However, the biggest savings are achieved when leakages can be prevented," says Vexve's Sales and Marketing Director, Maria Kalli.

Modern leakage detection is based on automated monitoring

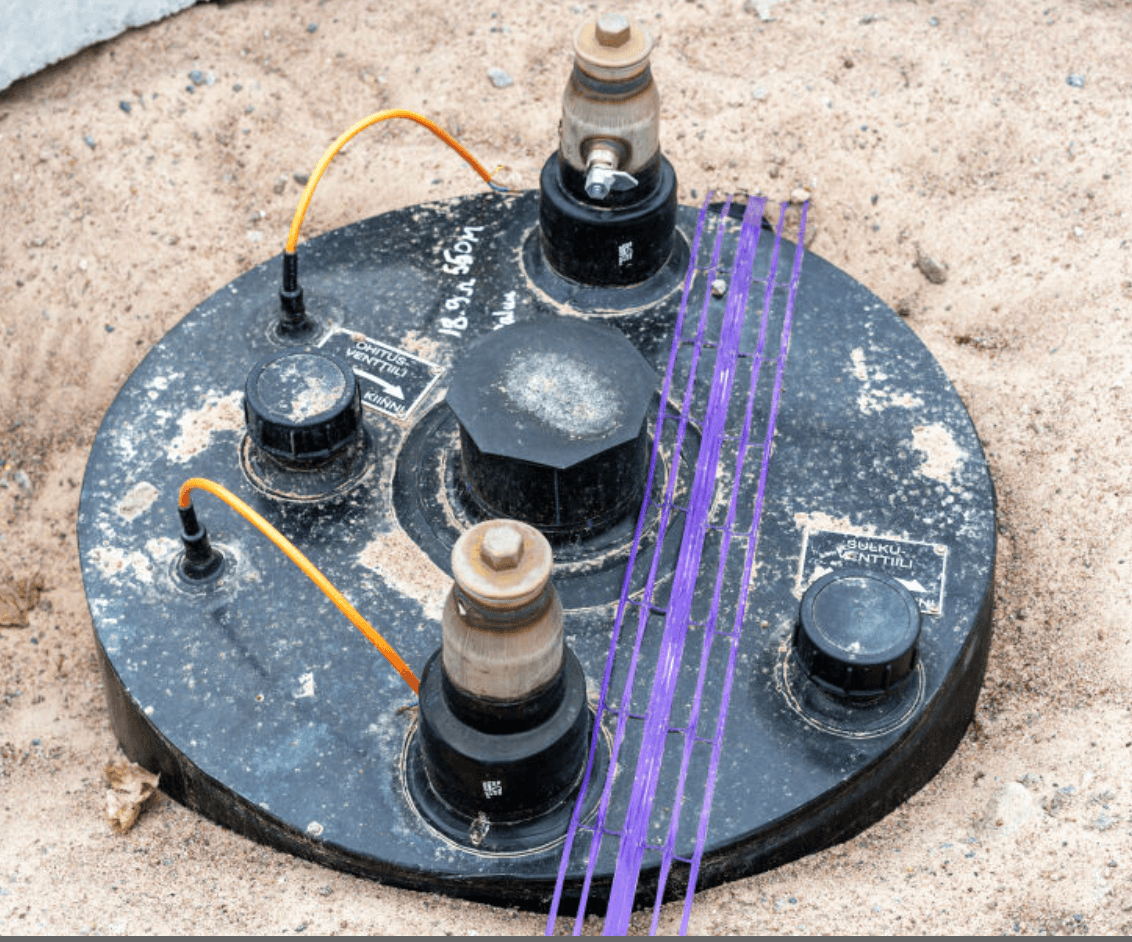

Accurate online monitoring of district heating lines is the basis of Vexve's iSENSE Pulse system. A wireless smart unit installed in a district heating network measures the internal moisture of the insulation case, as well as possible leakages in the pipes. Leakage detection is based on the interpretation of pulse reflections and localization is based on the travel time of the pulse. When the system detects a deviation, it sends the user an alarm about a detected leakage and notifies the user of the accurate location of the leakage.

Vexve's solutions as part of Fortum's substantial transfer line project

One of the most significant investments of Fortum's Espoo network area in recent years has been the new bioheat plant completed in Kivenlahti this year, as well as a transfer line that connects the plant to the existing network. The transfer line project comprised over 5 km of district heating line in the DN 500 pipe size in challenging conditions.

"Already at the planning stage of the line, we, together with Fortum and Caverion, who is responsible for the use and maintenance of the line, started to design the leakage detection system and its location within the network," says Maria Kalli about the start of the project two years ago. “In addition to automated leakage detection, Vexve's hydraulic Hydrox actuators and a control unit were installed in the transfer line, which allows the valves to be reliably remotely controlled."

Accurate localization of leakages with iSENSE Pulse

Since the installation of Vexve's iSENSE Pulse system, a deviation in the humidity measurements was detected in Espoo's new transfer line. The pipeline was dug up in accordance with the deviation notified by the system, and the leakage was found with an accuracy of 0.4% of the location notified by the system. The reason for the leakage was a tear in the seam of the insulation’s protective case. Significant corrosion had already accumulated in the leakage point, and within a few years, the leakage would have critically damaged the pipe.

"The system works great for leakage monitoring during the warranty period. It makes it possible to detect problems created already during installation, which means that damage can be repaired in good cooperation with the contractor already during the warranty period of the pipeline," says Kati Kupila, Fortum's Network Manager.

Digitalization as part of the district energy sector’s development

Changes in the operating environment of district heating companies are reflected, for example, as an increase in digitalization. With the help of services and products brought by digitalization, district heating companies can increase the efficiency and automation of their operations. With the iSENSE product family, Vexve wants to make its own contribution to the development of the district energy sector.

"The purpose of the new iSENSE product family is to provide our customers concrete tools for network monitoring and leakage detection," says Vexve's Sales and Marketing Director, Maria Kalli.

"We intend to utilize Vexve's leakage detection system also in future in the Espoo network area, particularly in longer transfer lines whose uninterrupted operation is important for us from the viewpoint of heat distribution," says Fortum's Network Manager, Kati Kupila.

Vexve products selected by Fortum for its transfer line project:

- iSENSE Pulse - Online leakage detection system

- Hydrox actuators and HCU remote control unit

- Vexve's DN 500 and DN 600 ball valves for district heating

- Vexve's DN 500 and DN 600 butterfly valves for district heating

Related brochures:

- Smart monitoring solutions for district heating networks

- Hydraulic control solutions

For more information:

Director, Sales and Marketing | Maria Kalli | +358 50 379 1730 |